To be carried out after machining and before the final heat treatment.

Heating to 600~650°C for 2 hours.

Introduction:

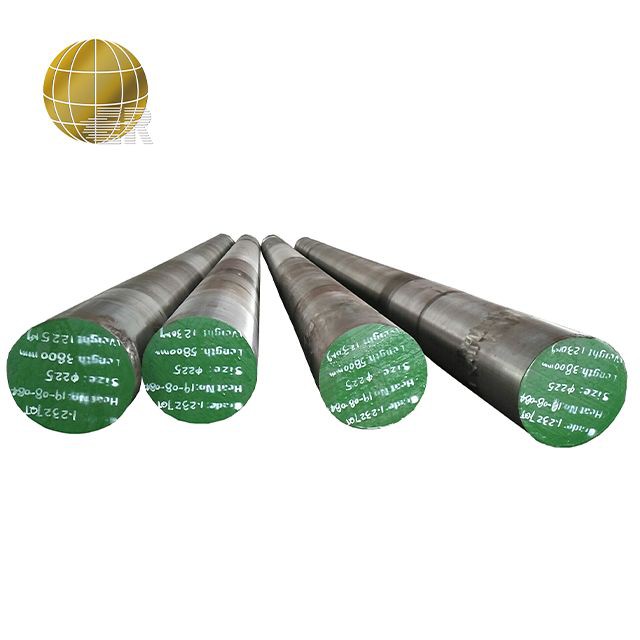

As a manufacturer of high-quality steel products, we are proud to introduce our latest product - Professional Peeled or Black AISI SAE 1045 steel. This type of steel is known for its excellent properties and versatility, which make it ideal for a wide range of applications in various industries.

Whether you are looking for a strong and durable material for manufacturing machinery parts, industrial tools, or construction equipment, our AISI SAE 1045 steel is sure to meet your needs. In this product introduction, we will take a closer look at the features and benefits of our steel, as well as the advantages of choosing our products over other options on the market.

Features:

One of the key features of our Professional Peeled or Black AISI SAE 1045 steel is its high carbon content, which gives it excellent strength and toughness. This type of steel is also known for its good weldability and machinability, which make it easy to work with and customize to meet specific requirements.

In addition, our AISI SAE 1045 steel is available in both peeled and black versions, depending on your needs and preferences. The peeled steel has a smooth and polished surface that is ideal for precision machining, while the black steel has a rougher texture that is better suited for more heavy-duty applications.

Benefits:

Choosing our Professional Peeled or Black AISI SAE 1045 steel offers a number of benefits for your business. Firstly, our steel is highly reliable and long-lasting, which means you can rely on it for a variety of applications without worrying about premature failure or wear-and-tear.

In addition, our AISI SAE 1045 steel is highly versatile, meaning it can be used in many different industries and applications. This includes manufacturing, construction, transportation, and more, making it a highly valuable material for businesses of all kinds.

Another benefit of choosing our steel is its cost-effectiveness. Despite being a high-quality and highly versatile material, our AISI SAE 1045 steel is competitively priced, making it an affordable option for businesses of all sizes and budgets.

Advantages:

There are several advantages to choosing our Professional Peeled or Black AISI SAE 1045 steel over other options on the market. Firstly, our steel is manufactured to the highest standards of quality and consistency, ensuring that each piece meets the same high level of performance.

In addition, we are committed to providing excellent customer service to our clients, ensuring that you receive timely and reliable support whenever you need it. We also offer fast shipping and delivery, meaning that you can receive your steel products quickly and efficiently.

Lastly, we are a China-based manufacturer, which means that we can offer highly competitive prices on our products. By sourcing directly from us, you can save money and benefit from our extensive experience and expertise in the steel manufacturing industry.

Conclusion:

In conclusion, our Professional Peeled or Black AISI SAE 1045 steel is a highly versatile, reliable, and cost-effective material that is ideal for a wide range of applications in various industries. If you are looking for a high-quality steel product that offers excellent value for money, then our AISI SAE 1045 steel is the perfect choice for you.

We invite you to contact us today to learn more about our products and services, and to find out how we can help you meet your business needs and goals. Thank you for considering our steel products, and we look forward to serving you soon.

Min. Order / Reference FOB Price | |

300 kg | US $5/ kg |

Port: | TIANJIN, SHANGHAI, DALIAN, QINGDAO, China |

Production Capacity: | 50000tons/Month |

Payment Terms: | L/C, T/T |

Type: | Round |

Standard: | AISI, ASTM, DIN, JIS, GB, BS |

Composition: | Stainless Steel Scrap |

Technique: | Cold Rolled |

Shape: | Bar |

Surface Treatment: | Black |

Special Use: High-strength Steel Plate, Wear Resistant Steel, Silicon Steel, Cold Heading Steel, Free Cutting Steel, Mold Steel

Application: Die Steel Bar

Specification: R: dia60-610mm; F20-300X100-610mm

Origin: Jiangsu,China

Chemical Analysis (%)

| C | Mn | Si | Cr | Ni | Mo | P | S |

0.36-0.42 | ≤1.00 | ≤1.00 | 12.5-14.5 | - | - | ≤0.03 | ≤0.03 |

Annealing

-Heat to 750~800°C, with hold at minimum rate for 3 hours.

-Furnace cooling.

Stress relieving

To be carried out after machining and before the final heat treatment.

Heating to 600~650°C for 2 hours.

Hardening

Preheating to 600~700°C;

- Austenitizing at 990~1040°C

- Oil or thermal bath cooling at 500~550°C, then oil cooling according to the steel shape and size.

Quenched hardness: HRC 52~56

Tempering

To be carried out after hardening according to the required hardness; at 170-270 °C in order to match hardness and resistance to corrosion; permanence for at least 2 hours;

Tempering must be repeated at least twice at a temperature 30 °C lower than the previous. Cooling in air.

Previous: Peeled Round Steel Bars

Next: No Information

Jan 20, 2021