The roller is the main working part and tool for continuous plastic deformation of metal on rolling mill.

Forged Steel Shafts - The Ultimate Choice for Heavy-Duty Applications

Are you looking for a reliable and durable solution for your heavy-duty applications? If yes, then our Forged Steel Shafts are the perfect choice for you. As a leading manufacturer of forged steel products, we take great pride in offering top-quality products to our clients worldwide.

Our Forged Steel Shafts are designed to provide maximum strength and durability, making them ideal for use in various industries, including construction, mining, oil and gas, and many others. The forging process helps to create a product that is both strong and ductile, allowing it to withstand high stress and pressure.

The Advantages of Forged Steel Shafts:

1. High Tensile Strength: Forged Steel Shafts are manufactured using a unique forging process that helps to align the grain structure of the steel, resulting in a product that has higher tensile strength and toughness than cast steel.

2. Improved Wear Resistance: Our Forged Steel Shafts are heat-treated to enhance their wear and corrosion resistance, allowing them to withstand harsh environments and extend their service life.

3. Greater Flexibility: Forged Steel Shafts are known for their greater flexibility as compared to other materials. This flexibility allows the shafts to handle higher levels of stress, vibration, and axial loads, making them an ideal choice for heavy-duty applications.

4. Low Maintenance: Forged Steel Shafts are low maintenance products, requiring minimal upkeep even in the most demanding environments.

5. Versatile: Our Forged Steel Shafts can be designed and manufactured to suit a wide range of applications, making them highly versatile and suitable for various industries.

Our Product Range:

We offer a broad range of Forged Steel Shafts, ranging from small to large sizes, and in various shapes, including round, square, and hexagon. Our products can be customized to meet your specific requirements, from material composition to surface finish.

Our manufacturing process involves strict quality control measures, ensuring that our customers receive products that meet or exceed their expectations. From raw material selection to finished products, we meticulously inspect every stage of production to ensure that our products are of the highest quality.

Why Choose Us?

1. High-Quality Products: We are committed to providing our clients with high-quality products that meet or exceed their expectations. Our Forged Steel Shafts are no exception.

2. Competitive Prices: As a manufacturer, we offer our products at highly competitive prices, ensuring that our customers receive excellent value for their money.

3. Timely Delivery: We understand the importance of timely delivery, and as such, we work tirelessly to ensure that orders are completed and delivered on time, every time.

4. Professional Service: Our team of experts is always available to provide professional advice and support to our clients, ensuring that they receive the best service possible.

Conclusion:

In conclusion, if you are looking for a durable, reliable, and versatile solution for your heavy-duty applications, look no further than our Forged Steel Shafts. With their high tensile strength, improved wear resistance, and greater flexibility, our Forged Steel Shafts are designed to meet the toughest demands of various industries. We are confident that our products will exceed your expectations, and we look forward to serving you.

FOB Reference Price

>=50 Tons

$8.00

Warranty:

1.5 years for machinery warranty

Lead Time:

Quantity(Tons) | 1 - 10 | 11 - 20 | >20 |

Est. Time(days) | 7 | 10 | To be negotiated |

Shipping:

Support Sea freight

Product Details

Overview

Quick Details

Place of Origin:

Jiangsu, China

Condition:

New

Type:

Bending Parts

Spare Parts Type:

shaft

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Marketing Type:

Hot Product 2019

Material:

ALLOY

Warranty:

1.5 years

After-sales Service Provided:

Online support

Key Selling Points:

Easy to Operate

Weight (KG):

5 KG

After Warranty Service:

Online support

Applicable Industries:

Machinery Repair Shops, Manufacturing Plant, Construction works , Energy & Mining

Local Service Location:

None

Showroom Location:

None

Tolerance:

Generally 0.05mm

Quality:

Top High

Supply Ability

500 Ton/Tons per Month

Packaging & Delivery

Plywood case

Port

TIANJIN, SHANGHAI, DALIAN, QINGDAO

Lead Time:

Quantity(Tons) | 1 - 10 | 11 - 20 | >20 |

Est. Time(days) | 7 | 10 | To be negotiated |

Product Description

The roller is the main working part and tool for continuous plastic deformation of metal on rolling mill. The roll is mainly composed of roll body, roll neck and shaft head. The roll body is the middle part of the roll which is actually involved in rolling metal. It has a smooth cylindrical or grooved surface. The roll neck is installed in the bearing and the rolling force is transmitted to the frame through the bearing housing and the press-down device. The shaft head of the transmission end is connected with the gear base through the connecting shaft, and the rotation moment of the motor is transferred to the roll. The rolls in the hot mill stand may be arranged in the form of two, three, four or more rolls.

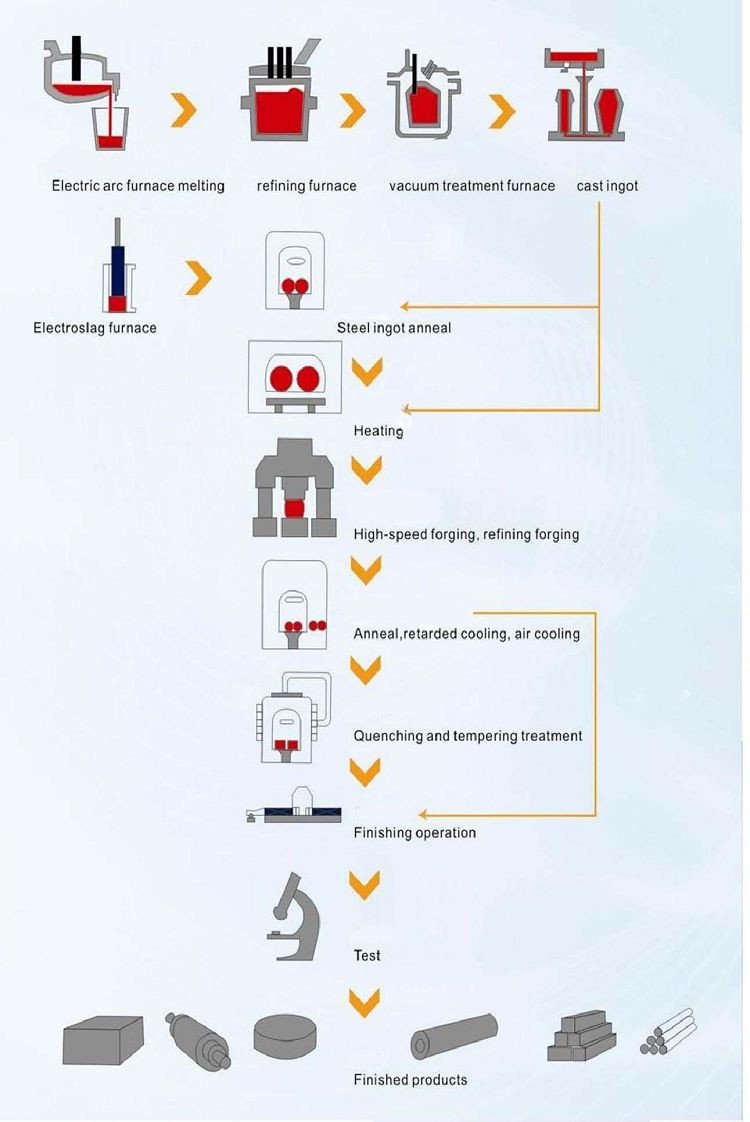

Product processing

Application

Production Inspection

Our heat treatment center with complete product testing equipment, for instance: the scanning electron micro sconezz(SEM).the transmission electron microscope(TEM)the material testing machine. the large-type metallurgical microscope,the endurance testing machine,the IAS-4 image analyzer, the American ARL direct- reading spectrometer, the American the electric ICP emission spectrometer, the American LECO infrared carbon sulfur analyzer, the hydrogen analyzer, the oxygen and nitrogen analyzer,the Swiss end harden ability tester, the German Zeiss inverted microscope, the Japanese CARTON stereo microscope, the 500J impact testing machine, the 500N hydraulic universal tester, the water immersion flaw detector, the radio element detector and so on.

Evergrowing Resources CO.,Ltd

Evergrowing Resources Co., Limited was Located in Nanjing, China. We have engaged in import and export of all kinds of ferrous and nonferrous materials all over the world. Because we are top agent of several different steel mills in Asia and Europe, so we have ability to offer best quality products and services to our clients. Till now, we have supplied products and services in Asia, Europe, Africa, North America and South America. Following the trend of market development, we have built our special steel processing center in Jiangsu, China to do further processing on the products, such as heat treatment (QT, N, ANN), rough turned, CNC cutting and etc. We have extended our industrial train and enhanced the ability to provide the auxiliary item, and thus strengthened our market advantage.

Previous: No Information

Next: Forged Steel Shafts

Jan 20, 2021