Basic Info. Model NO. AISI S2 Special Use High-strength Steel Plate, Wear Resistant Steel, Cold Heading Steel, Free Cutting Steel, Mold Steel Application Tool Steel Bar Od 20-600mm Transport Package in Seaworthy Packing, Anti-Rust Oil Painting Origin Mainland China Product Description Best...

Introduction:

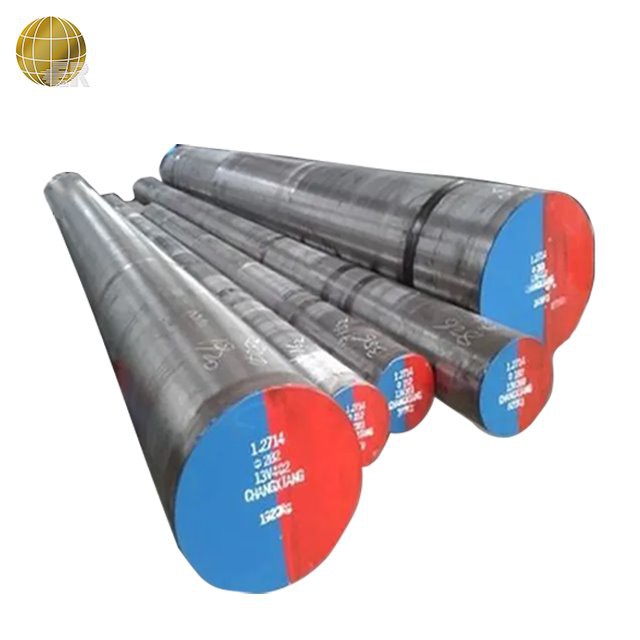

If you are looking for a high-quality tool steel that can provide unprecedented strength and durability, look no further than our product, Tool Steel Strength. At our manufacturing facility in China, we have spent countless hours perfecting the formulation and production of our tool steel to bring you a product that can withstand even the most demanding industrial applications. In this product introduction, we will discuss some of the key aspects that make Tool Steel Strength stand out from the competition and why it is such an attractive option for merchants looking to source top-quality tool steel.

Composition:

One of the most important aspects of any tool steel is its composition, as this ultimately determines its strength, toughness, wear resistance, and other key mechanical properties. At our facility, we use only the finest materials and alloys to create Tool Steel Strength, including chromium, molybdenum, vanadium, and tungsten. Together, these elements provide exceptional strength and durability, as well as excellent heat resistance and machinability.

Heat Treatment:

In addition to its composition, Tool Steel Strength also undergoes a precise heat treatment process that further enhances its mechanical properties. During this process, the steel is heated to a specific temperature and then cooled rapidly to produce a uniform, fine-grained structure that maximizes toughness and wear resistance. This heat treatment process is critical to ensuring that our tool steel has the strength and durability that are needed for demanding industrial applications.

Applications:

Speaking of industrial applications, Tool Steel Strength is an incredibly versatile material that can be used in a wide range of industries and applications. For example, it is commonly used in the manufacture of cutting tools, dies, molds, and other equipment that is subjected to high stress and wear over time. Its excellent heat resistance also makes it an ideal material for use in high-temperature applications, such as furnace parts and blades for gas turbines.

Benefits:

So why should merchants choose Tool Steel Strength over other types of tool steel? There are a number of key benefits that come with our product, including:

1. Unprecedented strength and durability: Our tool steel is designed to withstand even the most demanding industrial applications, providing reliability and longevity that can't be matched by other materials.

2. Excellent machinability: Despite its strength, Tool Steel Strength is also extremely easy to work with, making it a favorite among machinists and technicians.

3. High heat resistance: Thanks to its composition and heat treatment process, our tool steel can withstand high temperatures and maintain its strength even in extreme conditions.

4. Versatility: From cutting tools to dies to furnace parts, our tool steel can be used in a wide range of applications, making it a valuable resource for merchants who serve diverse industries and clients.

Conclusion:

In conclusion, Tool Steel Strength is an exceptional product that offers unparalleled strength, durability, and versatility for merchants who need top-quality tool steel. With its precise composition, rigorous heat treatment process, and universal applications, it is a product that can serve a wide range of industrial needs and provide confidence and reliability to merchants and their clients alike. Don't settle for less than the best – choose Tool Steel Strength and experience the difference for yourself.

Min. Order / Reference FOB Price | |

1 Ton | US $800-1,200/ Ton |

Port: | Shanghai, China |

Production Capacity: | 1000tons/Per Month |

Payment Terms: | L/C, T/T, Western Union, Money Gram |

Type: | Special Steel Bar |

Standard: | AISI, ASTM, DIN, JIS, GB, BS |

Composition: | Ferrous Steel Scrap |

Technique: | Forged |

Shape: | Bar |

Surface Treatment: | Polished |

Basic Info.

Model NO.

AISI S2

Special Use

High-strength Steel Plate, Wear Resistant Steel, Cold Heading Steel, Free Cutting Steel, Mold Steel

Application

Tool Steel Bar

Od

20-600mm

Transport Package

in Seaworthy Packing, Anti-Rust Oil Painting

Origin

Mainland China

Product Description

Best Choice for Alloy Steel Tool Steel

Chemical Composition:

C | Si | Mn | Cr | P | S | Mo | V | W |

0.40-0.55 | 0.80-1.20 | 0.30-0.50 | - | ≤0.03 | ≤0.03 | 0.30-0.60 | ≤0.50 | - |

Available size:

Round steel bar 60-800mm |

Flat steel bar 25-400mm*200-800mm |

Surface condition:

Black surface/ Grinded/ Machined |

Hardness

Annealed HBS217 max |

Characteristics:

Steel S2 Flat Bar / Die Steel S2 is a silicon-manganese tool steel which exhibits the highest impact toughness among all of the "S" type steels. The high toughness and the ability to be hardened to 58 Rockwell C make S-2 an excellent choice for applications which require higher strength than S-7 shock-resisting tool steel. |

Applications:

Brake Dies | Collets | Drift Pins |

Hand Chisels | Knockout Pins | Pipe Cutters |

Pneumatic Tools | Punches | Rivet Sets |

Shear Blades | Slitters | Swaging Dies |

Previous: 1.2312 Tool Steel

Next: D2 High Carbon Steel

Jan 20, 2021