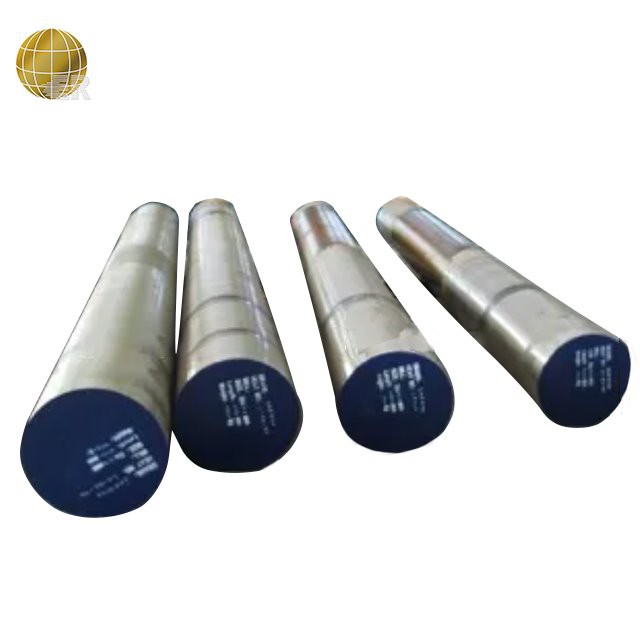

We could produce UNS N06230, 2.4733 forging/forged round bars with diameters ranging from 10MM to 6000MM and with weights from 10KGS to 15000KGS

Alloy 230 is an advanced alloy, developed with the latest technologies and engineering techniques that perform efficiently even in the most demanding environments. This high-performance nickel alloy is ideal for those who seek an alloy material that is versatile, durable, and reliable.

Our Alloy 230 is manufactured in the most advanced facilities, under strict guidelines, meeting the highest quality standards in the industry. We have incorporated innovative technologies that make our Alloy 230 stand out from other materials in the market.

Our Alloy 230 is perfect for industries that demand high-temperature performance, such as aerospace, chemical processing, power generation, thermal processing, and petrochemical processing. In these industries, the material needs to withstand intense heat and pressure, aggressive chemicals, and corrosive environments.

Here are some reasons why you should choose our Alloy 230:

1. High-Temperature Performance: Our Alloy 230 offers superior resistance to high temperatures, making it perfect for use in environments with temperatures ranging from cryogenic to 2100°F. The material retains its strength and resists deformation and creep even under high stress.

2. Durable and Corrosion-Resistant: Our alloy 230 is immune to the corrosive effects of concentrated acids and alkaline solutions. It has excellent resistance to oxidation and reduction environments, making it durable in environments such as chemical plants, refineries, and power plants.

3. Versatility: Our Alloy 230 can be used in various applications due to its excellent mechanical properties. The material is ductile, allowing it to be easily formed and shaped into different configurations. The material can also be welded or brazed using standard techniques.

4. Cost-Effective: Our Alloy 230 can be a cost-effective solution compared to other materials with similar performance. Due to its excellent resistance to high temperatures and corrosive environments, our Alloy 230 requires less maintenance and has a longer service life, reducing replacement costs and downtime.

5. Easy Availability: Our Alloy 230 is readily available in a variety of sizes and shapes, making it simple to meet your requirements.

Our Alloy 230 has been used in various applications, and some of the examples include:

1. Aerospace: Our Alloy 230 has been used in jet engines, gas turbines, and aircraft exhaust systems.

2. Chemical Processing: Our alloy 230 is used in chemical reactors, heat exchangers, and other equipment in chemical plants.

3. Power Generation: Our Alloy 230 is used in gas turbines, steam turbines, and heat exchangers in power plants.

4. Thermal Processing: Our Alloy 230 is used in high-temperature furnaces, ovens, and incinerators.

5. Petrochemical Processing: Our Alloy 230 is used in various applications in refineries and petrochemical plants.

In conclusion, our Alloy 230 is an advanced material with excellent high-temperature performance, corrosion resistance, versatility, and cost-effectiveness. It is the ideal material for use in demanding environments, ensuring longevity and reliability of equipment. Our Alloy 230 is readily available in various sizes and shapes, and we are committed to providing professional service to meet your requirements. Contact us today for more information on how our Alloy 230 can meet your needs.

OB Price:US $1 / Piece

Min. Order:1 Piece

Production Capacity:5000 Tons/Year

Transport Package:Wooden or Steel Frame Crate Packing

Payment Terms:T/T

Basic Info.

Model NO.:jj551

Processing Object:Metal

Molding Style:Forging

Molding Technics:Forging

Application:Machinery Parts

Material:Steel

Heat Treatment:Quenching

Surface Treatment:Polishing

Forging Tolerance:+/-0.5mm

Standard: AISI

Trademark: Evergrowrs

Specification: CE

Origin: Jiangsu,China

Product Description

We could produce UNS N06230, 2.4733 forging/forged round bars with diameters ranging from 10MM to 6000MM and with weights from 10KGS to 15000KGS

The melting method of UNS N06230, 2.4733 material is ESR+VIR or VIM+ESR+VAR

Our UNS N06230, 2.4733 forged/forging round bars are widely used in in chemical plants and heavy vessels, pump and valve producers, and industrial blades. Separators and centrifuges, Cement industry and sugar industry, drilling platform, drilling rig, pipelines and refineries, power generation and power plants, , generators, compressors, gear boxes. Oil & gas industry, concrete mills and mixers, processing units, crystalizer equipment and so on

Our UNS N06230, 2.4733 forged/forging round bars could be 100% Ultrasonic Inspection as per the forging parts UT Test standard of ASTM A 388 or EN10228.

We could supply UNS N06230, 2.4733 forged/forging round bars material certificate as per the standard of EN10204-3.1 or EN10204-3.2 of third party

Any inquiry UNS N06230, 2.4733 forged/forging round bars, please feel free to contact us. We are glad to quote the best price for every clients

Heat treatment:

Normalized / Annealed / Quenched / tempered

Surface Treatment:

painting,plating,polishing,black oxide,transparent anti-rust oil

Quality control:

UT,MT,RT,PT,chemical composition test,mechanical property test,etc.

Inspection:

1, Raw material certificate(material chemical composition) 2, Heat treatment sheet report

3, Dimension inspection report 4, UT test report

Delivery condition:

Hot forged +Rough machined (black surface after Q /T)+ Turned

Competitive Advantage:

Quality control and management to the whole produce process, including ingot smelting, forging, heat treatment, machining and strictly final inspection prior to delivery.

Excellent product quality and service, competitive price, "in-time" delivery

Previous: No Information

Next: 42crmo4 Steel

Jan 20, 2021