Hot Rolled Alloy Steel Round Bar: A Superior Product for Your Business Needs

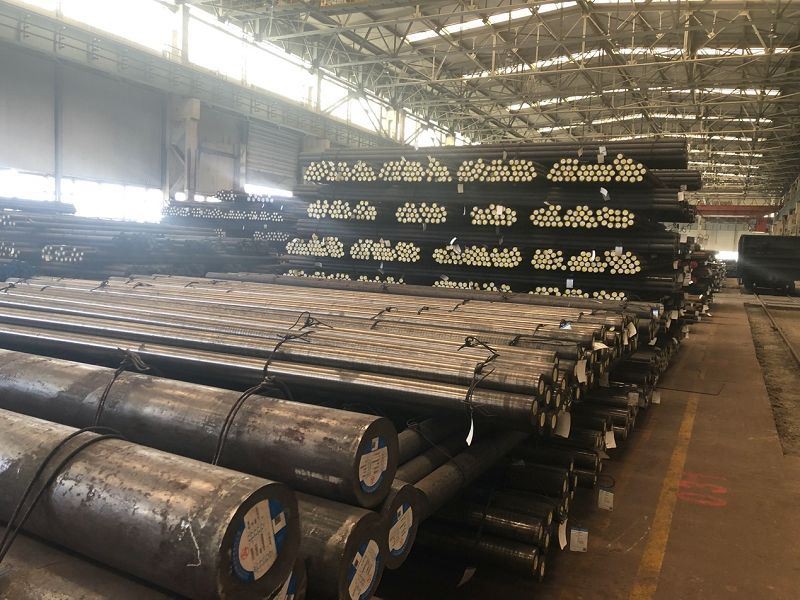

If you are looking for a high-quality product that can make your business stand out, Hot Rolled Alloy Steel Round Bar may be the perfect solution. As a manufacturer of this product, we have perfected the manufacturing process to ensure that our customers receive the best possible product. Here are some things you should know about Hot Rolled Alloy Steel Round Bar, and why it is a great choice for your business needs.

What is Hot Rolled Alloy Steel Round Bar?

Hot Rolled Alloy Steel Round Bar is a type of steel that is formed by rolling it into a round shape, and then heating it to a high temperature to make it malleable. This process allows us to create a stronger, more durable product that is ideal for a wide range of applications in various industries.

What Are the Advantages of Hot Rolled Alloy Steel Round Bar?

Hot Rolled Alloy Steel Round Bars have many advantages over other types of steel products. Firstly, the Hot Rolled Alloy Steel Round Bar is more durable and can stand up to more wear and tear than other types of steel. It is also more resistant to corrosion, which means it lasts longer and requires less maintenance.

In addition, Hot Rolled Alloy Steel Round Bar has excellent tensile strength, which makes it ideal for use in applications where the material will need to support a lot of weight or force. The material is also more resistant to heat, which makes it ideal for use in high-temperature environments.

Why Choose Hot Rolled Alloy Steel Round Bar?

There are many reasons why Hot Rolled Alloy Steel Round Bar is an excellent choice for your business. Firstly, our Hot Rolled Alloy Steel Round Bar is of superior quality, which means your customers will be getting a product that is reliable and long-lasting. Furthermore, our Hot Rolled Alloy Steel Round Bar can be customized to meet the specific needs of your business, such as size, shape, and length, which means you can get the product that works best for your needs.

In addition, we offer competitive pricing and fast delivery times, so you can rest assured that you are getting a high-quality product at a reasonable price. Our Hot Rolled Alloy Steel Round Bar is also available in a wide range of sizes and shapes, which means you can find the perfect product to fit your specific needs and requirements.

What are the Applications of Hot Rolled Alloy Steel Round Bar?

Hot Rolled Alloy Steel Round Bar is an ideal material for a wide range of applications. It is commonly used in the construction industry, for applications such as building frames, bridges, and other structural elements. It is also used in the manufacturing industry, for applications such as machinery and equipment, tools and dies, and other industrial products.

Hot Rolled Alloy Steel Round Bar is also used in the automotive industry, for applications such as suspension components, steering mechanisms, and other parts that require high-tensile strength and corrosion resistance. Furthermore, it is used in the oil and gas industry, for applications such as drill collars, pipes, and other oil and gas equipment.

Conclusion

In summary, Hot Rolled Alloy Steel Round Bar is an excellent choice for your business needs. It offers superior durability, corrosion resistance, and strength, making it a great investment for any application requiring high-quality steel. With customizable sizes, shapes, and competitive pricing, our Hot Rolled Alloy Steel Round Bar is the perfect solution for your business. Contact us today to learn more about our products and how we can help you reach your business goals.

Product Details:

Place of Origin: China

Brand Name: Evergrowrs

Certification: ISO,ect.

Model Number: As per standard

Payment & Shipping Terms:

Minimum Order Quantity : 10 Tons

Price: USD 200/1500/Ton

Port: Shanghai,Tianjin,Dalian,Qingdao,China

Ackaging Details: Nude in bundle

Payment Terms: L/C,T/T,Western Union,Paypal, Money Gram

Delivery Time: 40~50 days

Supply Ability: 50000 Ton/Tons per Month

Detailed Product Descriptions:

Shpe: Round/square.etc Alloy or Not: is alloy Special Use: Die Cuting Mold Steel/Free Cutting Technique: Forging Standard: ASTM,GB,ASTM,ASIS Length: 200mm-600mm Grdae: 30CrMo Surface: Black,Peeled,Turned,Grinded Our Service: 24 Hours Online & Prompt Reponse |

Specifications:

| Production Name | 35CrMo AISI 4140 Hot rolled round bar alloy steel |

| Main Grade | 35CrMo |

| Shpae | Round alloy steel,ect |

| Diameter | 20-200mm |

| Length | 2000-5800mm |

| Technique | Hot rolled |

| Surface | Black, Rough Machined, Turned |

| Test | SGS/UT100%Elements Testing |

| Introduction | 35CrMo is the specification number of alloy structural steel (alloy quenched and tempered steel). This steel is mainly used for manufacturing important parts of various machines that bear impact, bending and torsion, and high load |

Fabrication and Heat Treatment

It is used to manufacture important parts of various machines under impact, bending, torsion and high load, such as herringbone gear, crankshaft, hammer bar, connecting rod, fastener of steel rolling mill, main shaft and axle of steam turbine engine, transmission parts of engine, large motor shaft, piercer in petroleum machinery, bolts for boiler with working temperature lower than 400 ºC, nuts with working temperature lower than 510 ºC, chemical machinery Medium and high pressure seamless thick wall pipe (temperature 450 ~ 500 ºC, no corrosive medium), etc.; it can also replace 40crni for manufacturing high load transmission shaft, turbine engine rotor, large section gear, supporting shaft (diameter less than 500mm), etc.; equipment materials, pipematerials, welding materials, etc. in process.

Mechanical properties of 35CrMo round steel

(1) Material characteristics: the steel has good machinability, after machining forming, cavity deformation and size becomes smaller, after heat treatment can improve the surface hardness, improve the service life of the mold. Adding a normalizing or annealing procedure before quenching and heating can further improve the mechanical properties of materials by refining grains and eliminating networked ferrite and banded structure.

The steel has high static strength, impact toughness and fatigue limit. Its hardenability is higher than that of 40Cr steel. It has high creep strength and rupture strength at high temperature. In cold deformation, the plasticity is medium and the weldability is poor.

(2) Supply status: normalization, annealing, high temperature tempering or delivery without heat treatment. Annealed state, hardness ≤ 229HbW.

(3) Chemical composition: according to standard GB/T 3077-1999, the chemical composition (mass fraction) of the steel: C0.32, Mn0.40% % ~ 0.40% ~ 0.70%, Si0.20% ~ 0.40%, Cr0.80, Mo0.15% % ~ 1.10% ~ 0.25%, S acuities were 0.035%, 0.035% or less, Ni P acuities were 0. 30%, C 0.25% or less.

(4) refer to the corresponding brand: German DIN material number 1.7220, German DIN standard number 34CrMo4, Chinese GB standard number 35CrMo, British BS standard number 708A37, British EN standard number 19B, French AFN0R standard number 35CD4, Italian UNI standard number 35CrMo4, Belgium NBN standard grade 34CrMo4, Sweden SS standard grade 2234, Spain UNE standard grade 34CrMo4, Japan JIS standard grade SCM432/SCRRM3, the United States AISI/SAE standard grade 4137; 4135.

(5) Mechanical properties: tensile strength ≤ 985Mpa, yield strength ≤ 335Mpa, elongation 12%, section shrinkage ≤45%, impact absorption energy ≤63J, impact toughness ≤78J/cm2

(6) Critical point temperature (approximate): AC1 =755°C, AC3 =800°C, AR3 =750°C, AR1 =695°C, MS =271°C

(7) complete annealing specification: annealing temperature 830 ~850°C, insulation 2 ~3h, furnace cold to 500°C, air cooling, hardness 197 ~ 229HbW.

(8) Quenching and tempering specifications: quenching temperature 850°C. Oil cooling, tempering temperature 550°C, water cooling or oil cooling. The blank thickness is 25mm, the tensile strength is 1000MPa, the yield strength is 850MPa, the elongation is 12%, and the impact toughness is 80J/cm2

(9) typical application example: suitable for large section aluminum, magnesium alloy die casting mold

certificate

Previous: 1095 High Carbon Steel

Next: Hot Rolled Carbon Steel

Jan 20, 2021